Prop Plane in the Mountains Drawing

Through the years, many different types of aircraft propellers were experimented with. Some more successful than others. Notice out some of the nigh mutual types of propellers in aircraft and learn the differences between each of them.

The device that converts rotational energy generated by the engine or any other mechanical source into propulsive force is chosen a propeller. Propellers are an essential part of the aircraft as without them an plane cannot fly.

At that place are dissimilar types of aircraft propellers available today. We will look at some of the most common types of aircraft propellers and come across how they are different from one another.

one. Fixed-Pitch

The propeller that has the blade bending or blade pitch fabricated into the propeller is categorized every bit a stock-still-pitch propeller. One time the propeller has been built, the bract bending can't be inverse. Fixed-pitch propellers are generally one slice and made of aluminum alloy or wood.

These propellers are designed to provide the best efficiency at forwarding speeds. They fit a specific set up of conditions of both engine and airplane speed. Any alter in those conditions reduces both the propeller and engine efficiency. Fixed-pitch propellers are used on airplanes of low speed, power, altitude, or range.

Many single-engine aircrafts take fixed-pitch propellers installed on them and the advantages they offer include simple operation and less expense. These propellers don't crave control input from the airplane pilot during the flying.

Fixed-pitch propellers are further categorized into wooden propellers and metal propellers.

Wooden Propellers

Wooden stock-still propellers or wooden propellers are hardly plant in the aircrafts of today, but they were widely used before the introduction of metal propellers. These propellers were built layer by layer with specially prepared forest. Black walnut wood, carbohydrate maple woods, yellowish birch wood, and black cherry wood were most usually used in the making of these now vintage wooden propellers.

Metal Propellers

The first metal propellers were used in the aircrafts for armed forces operations during 1940. These propellers were made using incredibly strong and durable aluminum blend. The metal material used in the making of these propellers was treated to raise its properties and make it less prone to warping from damage due to rut or cold. Today, information technology is difficult to discover an shipping propeller made of anything just metal.

2. Ground-Adjustable Propeller

The operation of basis-adjustable propellers is similar to that of a stock-still-pitch aircraft propeller. The blade bending or pitch can only be changed when the propeller isn't turning. A clamping machinery holds the propeller bract in place. The blade angle can be changed by loosening this mechanism.

In that location is no way to change the blades' pitch during the flying to run across variable requirements, which is one of the reasons why basis-adaptable propellers aren't used in modern shipping.

3. Controllable-Pitch Propellers

Every bit the name suggests, the bract pitch or angle of a controllable-pitch propeller can be changed during flight while the shipping propeller is still running. This means that the blade angle of the propeller can exist changed to see flight weather.

Nevertheless, the number of pitch positions is limited – the pitch might be adjusted to angles betwixt the maximum and minimum pitch settings of the propeller. With controllable-pitch propellers, it is possible to attain a detail engine rpm to encounter specific flight conditions.

It is easy to misfile controllable-pitch propellers with a constant-speed propeller, but the two are dissimilar. Controllable-pitch propellers allow the blade angle to exist changed while the propeller is turning. However, the propeller blade must be inverse direct by the airplane pilot. The blade bending of the propeller will not alter until the pilot alters it. On the other hand, the blade angle of a constant-speed propeller can change automatically.

4. Abiding-Speed Propellers

Abiding-speed propellers speed up when the airplane dives and slows down when information technology climbs due to the changing load on the engine. To ensure that the propeller provides an efficient flight, the pilot tries to keep the speed equally constant as possible. The mechanism that allows a constant-speed propeller to work is known as propeller governor. A propeller governor senses the aircraft engine's speed and changes the bract angle of the propeller to maintain a specific rpm regardless of the aircraft's operational conditions.

Using propeller governor for increasing and decreasing propeller pitch allows the pilot to go along the engine speed abiding. When the aircraft climbs, the propeller's blade angle decreases, preventing the aircraft's engine speed from decreasing.

When the aircraft goes into a dive, the propeller'south blade angle increases, preventing overspeeding and so the power output doesn't change – since there is no change in throttle setting.

If the aeroplane's throttle settings are inverse instead of irresolute its speed past diving or climbing, the propeller's blade angle decreases or increases every bit required to maintain a constant rpm. The power output of the engine changes in accordance with alterations in the aircraft's throttle setting.

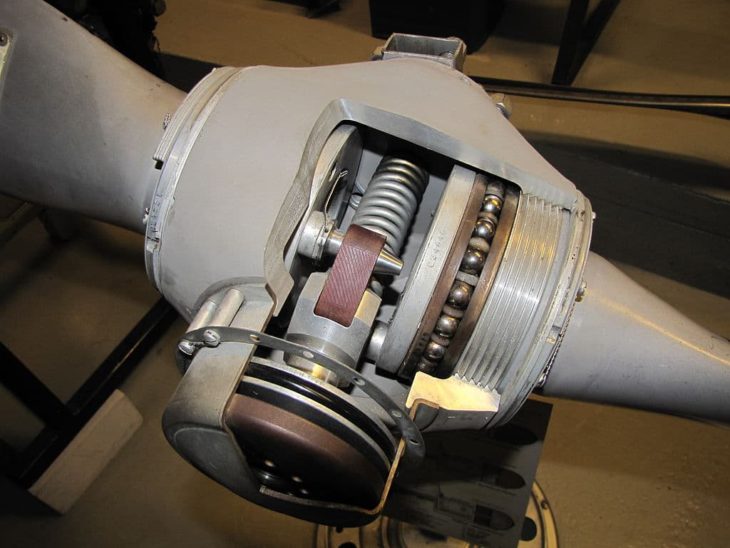

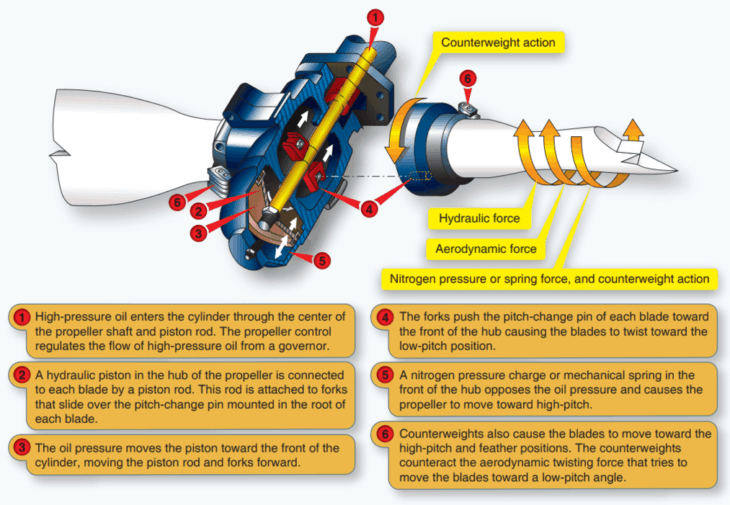

The pitch-irresolute mechanism of a constant-speed propeller uses a piston and cylinder system and is operated hydraulically using oil pressure. Either cylinder will move over a piston or the piston will move in a stationary cylinder. The piston'due south linear motion is converted into rotary movement by different kinds of mechanical linkages to alter the propeller'south blade angle. Gears may exist used for the mechanical connection – the pitch-changing mechanism responsible for turning each blade's butt. A bearing is mounted on each blade that allows them to rotate to change the blade bending.

The oil pressure required to operate the various pitch-changing mechanisms hydraulically comes direct from the engine lubricating system. Higher oil pressure level provides a quick blade angle change. The pressurized oil is directed by the governor for the operation of the propeller'southward pitch-irresolute mechanism.

The governor used for controlling pitch-irresolute mechanisms of a propeller is connected to the crankshaft of the aircraft's engine and responds to changes in the engine rpm. When the rpm increase to a higher place its fix value, the governor causes the pitch-changing mechanism of the propeller to increment the bending of the blades. The change in angle puts increased load on the aircraft's engine and the engine rpm decrease.

When the engine rpm decreases below the specific value of the governor (for which the governor is set), then the governor causes the pitch-changing mechanism of the propeller to decrease the angle of the blade. This decreases the load on the engine thereby increasing the rpm. In this manner, the governor tends to go along rpm constant.

In a constant-speed propeller, the control arrangement automatically adjusts the pitch with the assistance of a governor to maintain a preset engine rpm. So pilot's attention isn't required to adjust the pitch of the propeller.

For case, if the speed of the engine increases, an overspeed condition will occur and the propeller volition demand to slow down. The governor automatically increases the propeller's blade angle until the desired rpm has been established. Adept constant-speed propellers respond to modest variations to ensure that a abiding engine rpm is maintained throughout the flying.

five. Feathering Propellers

These propellers are used with multi-engine aircrafts. If ane or more than engine fails, then these propellers reduce propeller drag to a minimum. Feathering propellers can change the blade angle of a propeller to approximately 90 degrees. Propellers are normally feathered when the engine of the aircraft fails to generate the power required to turn the propeller.

The propeller blade is rotated to an angle parallel to the line of flying to profoundly reduce the drag on the airplane. When the blades go parallel to the airstream, aircraft'southward propeller stops turning and windmilling is minimized.

In the majority of modest feathering propeller, oil pressure is used to subtract the propeller's bract angle while bract flyweights, compressed air, and springs are used to increase the blade angle.

Latches lock the aircraft'due south propeller in the low blade angle as information technology slows down at engine shutdown. Latches tin can be external or internal and are located inside the propeller hub. Centrifugal force holds the latches off their seat during a normal flight to ensure that they don't stop the blades from feathering.

6. Opposite-Pitch Propellers

Reverse-pitch propellers are controllable propellers whose blade angles may be changed to a negative value in-flight. The purpose of a reversible pitch is to create a negative bract angle to produce thrust in the reverse direction. Propeller blades may exist moved to a negative pitch subsequently the plane has landed to make it come to a complete stop. As the blades of the propeller move into a negative bending, the engine ability increases negative thrust. This slows down the shipping aerodynamically and reduces ground roll. Reversing the propellers quickly reduces aircraft speed after touchdown and minimizes brake habiliment.

The Hercules C-130, with its constant-speed fully feathering reversible propellers is able to opposite using reverse pitch equally you can run into in the video below (toward the end of the video).

Related Posts

- Do Airplanes Recycle Air? Do Airplanes Bring in Fresh Air?

- What is a Yaw Damper? How the Yaw Damper Works and Why Information technology's Needed

- What are Canards (Benefits and Drawbacks) + six Famous Canard Planes

fenstermachersquirequisen.blogspot.com

Source: https://aerocorner.com/blog/types-of-aircraft-propellers/

0 Response to "Prop Plane in the Mountains Drawing"

Post a Comment